Artificial Intelligence for Machine Vision

Increasingly, industry is turning to deep learning technology to solve manufacturing inspections that are too complicated, time-consuming, and costly to program using traditional machine vision. Cognex ViDi is the first deep learning-based software designed to solve these complicated applications for factory automation.

Manufacturing advantages

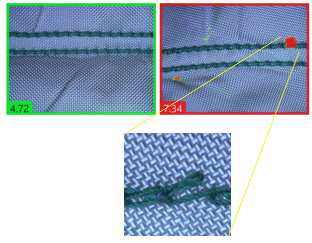

Deep learning technology uses neural networks which mimic human intelligence to distinguish anomalies, parts, and characters while tolerating natural variations in complex patterns. Deep learning offers an advantage over traditional machine vision approaches, which struggle to appreciate variability and deviation between very visually similar parts.

Deep learning-based software optimized for factory automation can:

- Solve vision applications too difficult to program with rules-based algorithms

- Handle confusing backgrounds and poor image quality

- Maintain applications and re-train on the factory floor

- Adapt to new examples without re-programming core algorithms

- Be used by non-vision experts

In factory automation, deep learning-based software like VisionPro ViDi can now can perform judgment-based part location, inspection, classification, and character recognition challenges more effectively than humans or traditional machine vision solutions.

Smarter Machine Vision AI – Now with Color

The Addition of Color greatly increases the amount of data available which allows for the Deep learning of the Cognex VIDI to perform more sophisticated decision making.

The Addition of Color greatly increases the amount of data available which allows for the Deep learning of the Cognex VIDI to perform more sophisticated decision making.