Home / Manufacturers / FANUC

FANUC

Reach Your Manufacturing Goals in Any Industry

FANUC has the robotics products and expertise to help you succeed. With more than 100 robot models and over 40 years of helping manufacturers achieve their production goals, we're ready for any manufacturing challenge in any industry. FANUC robots for manufacturing are easy to operate and provide complete flexibility thanks to a range of application-specific options, straightforward integration, payloads up to 2,300kg and maximum reaches up to 4.7m.

Robot Offering

CRX Collaborative Series

FANUC’s new CRX Cobots are safe, flexible, quick to implement, and easy to program. All with FANUC renowned reliability and 8 years of maintenance-free operations to meet the production needs of today’s manufacturers.

LR Mate Series

The FANUC LR Mate is a compact 6-axis robot with the approximate size and reach of a human arm. It combines best-in-class robot weight-load capacity with standard IP67 protection and outstanding FANUC quality. This makes the LR Mate the best and most reliable mini robot for process automation in many industries.

SCARA Series

Looking for a way to level up the speed, precision and repeatability in manufacturing processes that require a 3kg-20kg payload? Our SCARA line of robots have been used in manufacturing applications in everything from automotive,

medical device, assembly and pick and place packaging.

R Series

Fast, slim, reliable – capable of handling up to 130 kg and reaching up to 2.2 m, the R-1000iA Series is ideal for handling applications involving medium payloads including welding, handling and palletizing. Available in 5, 6 or 7 axes, this robot series is ideal for material handling and robotic spot welding, while its slim design and small footprint help to save floor space.

Delta Series

Discover the unique, ultra-compact FANUC Delta Series Robot and enter a new dimension in high-speed small parts handling. With 3, 4 or 6 axes, this series of high-speed delta robots is ideal for a variety of applications requiring a maximum payload of 12 kg and a work envelope of up to 1,600 mm.

Through their ability to be mounted in multiple positions, FANUC Delta's can be installed directly into the most compact of machines. As versatile as the human hand, they make an ideal alternative to complicated and expensive hard automation.

Toploader Series

FANUC’s series of toploaders are overhead, rail-mounted robots offering six-axis articulation, a modular construction and are electric servo-driven. With a wide selection of rail lengths, a payload range of 20 to 200 kg, and reach of 1.6 to 2.2 meters, the toploader series is ideal for a variety of industries and applications. FANUC offers the most versatile line of toploader robots in this class.

Robotic Applications

FANUC can support a wide-variety of robotic applications like those featured here.

Machine Tending

Automating these machines gives manufacturers clear advantages regarding utilization, secondary processes, labor resources, and productivity.

Anytime a machine sits idle or an operator isn’t available to support it, that equates to lost productivity and profits.

Palletizing/ Depalletizing

Automating palletizing can make your operations safer and more profitable. Whether you’re stacking a full layer or individual boxes, bags, pails or drums, FANUC’s palletizing cobots and robots offer a fast, steady, and reliable automated solution.

Their extensive offerings provide many options in terms of size, payload, speeds for cycle time and precision and most importantly, care in handling your products.

Assembly

Robotic assembly is likely one of the first images people have when they think of industrial robots. Automotive manufacturing – essentially the first industry to standardize on robotic automation – utilizes heavy-duty six axis robots to increase capacity and improve quality in their manufacturing processes.

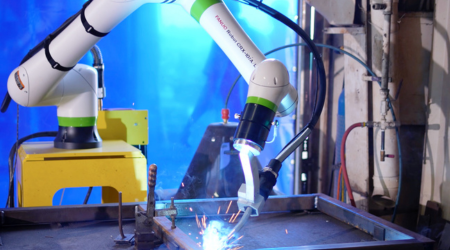

Welding

Manufacturers who automate their manual welding processes by using robotic welders immediately see advantages including improved cost-effectiveness, improved weld consistency, the ability to reach difficult welds, higher repeatability, and improved floor space savings.

CRX Collaborative Robots

FANUC’s new CRX Cobots are safe, flexible, quick to implement, and easy to program.