Machine Safety

Machine Safety refers to the measures and practices implemented to protect individuals, property, and the environment from potential hazards associated with machines and industrial equipment. It encompasses a range of strategies, technologies, and protocols designed to minimize the risks of accidents, injuries, and damage in industrial and manufacturing settings. To achieve machine safety, we employ various measures, including physical machine guarding, light curtains, mats, scanners, interlocks, emergency stop mechanisms, etc. Advancements in safety technology have led to more sophisticated safety systems that can detect and respond to potential hazards quickly, further enhancing machine and operator safety.

Machine Safety Projects

.jpg)

Crosswalk Forklift Detection

Safety radar scanners monitor the operator walkways in high-traffic areas and notify forklift drivers via overhead hazard lights to stop/use caution when passing through. By providing real-time detection and rapid response capabilities, these scanners help create a safer working environment, reducing the risk of collisions and ensuring thewell-being of workers and pedestrians.

.jpg)

Robotic Palletizer Safety

This robot cell incorporates access guarding and restart prevention utilizing mechanical barriers, light curtains, and safety radar system. This solution ensures no operators or forklifts enter the designated area while the robot is in operation. It also ensures the palletizer will not restart until every operator is out of the hazard zone.

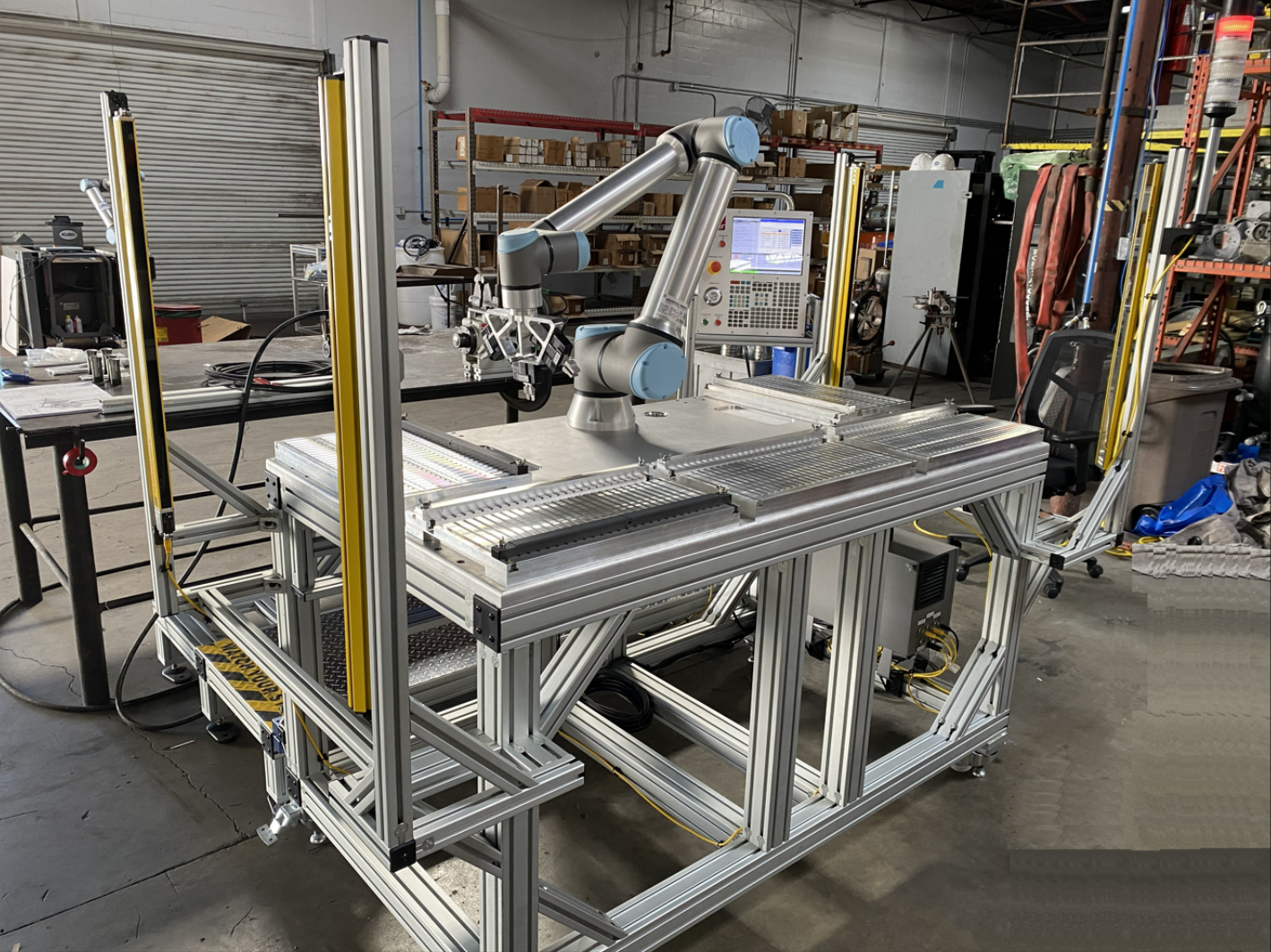

Machine Tending Station Safety

The robot cell is equipped with a set of light curtains to form a protective barrier around the outer perimeter of the machine. This protective barrier is designed to allow the operator to load parts safely while the machine is in operation. If any of the light curtains are obstructed, the robot will enter a reduced mode.

The machine is also equipped with a safety scanner to detect operators or objects on the catwalk in between the robot table and the CNC machine. This protective barrier allows the operator to interact with the CNC machine during calibration sequences and troubleshooting. If the scanner is obstructed, the robot will stop.

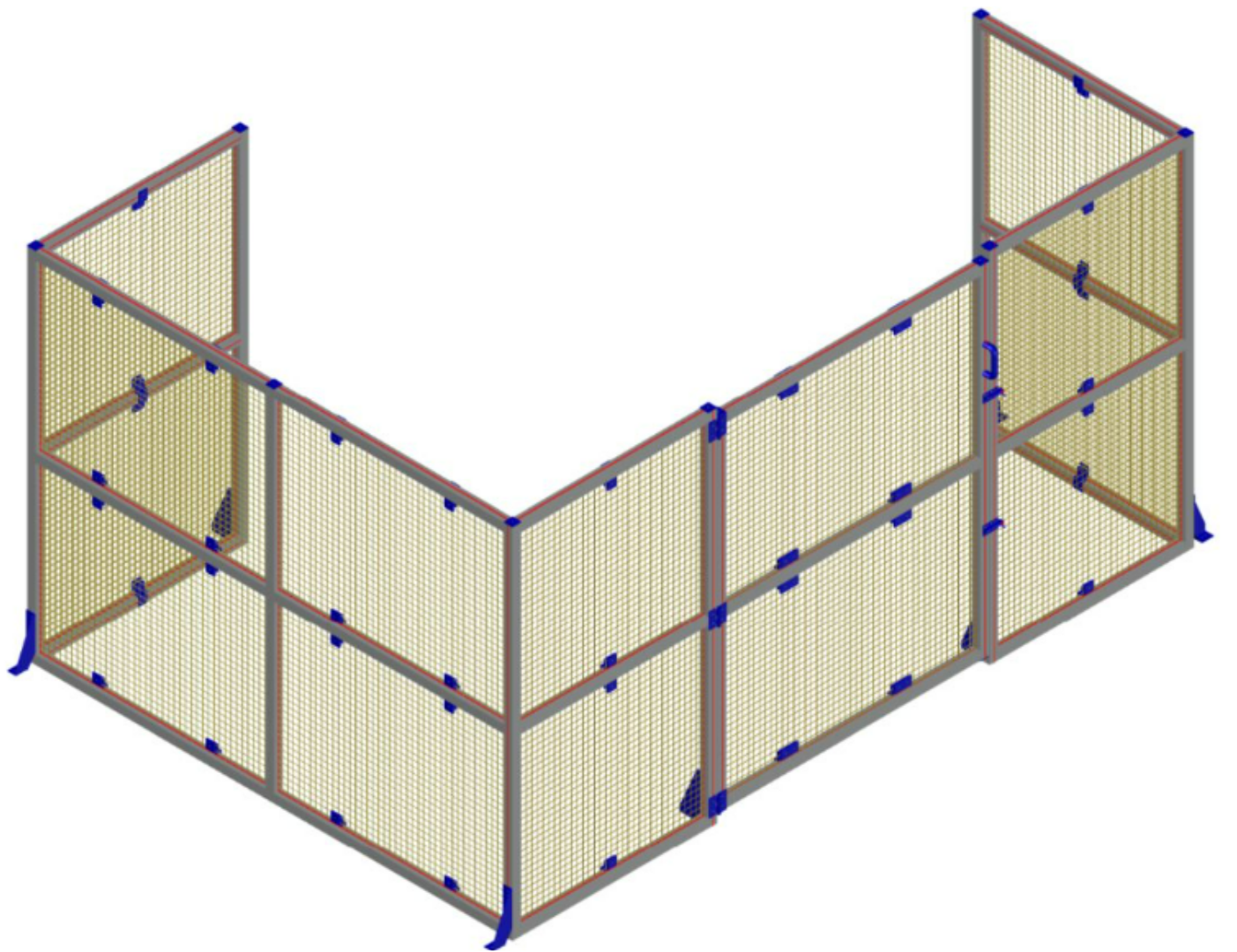

Machine Perimeter Guarding

A customer had new machines arriving but needed proper safety guarding prior to operation. Our engineering team worked with the customer to create a 3D model of the design to ensure proper fit, help with assembly, and verify the desired aesthetics.

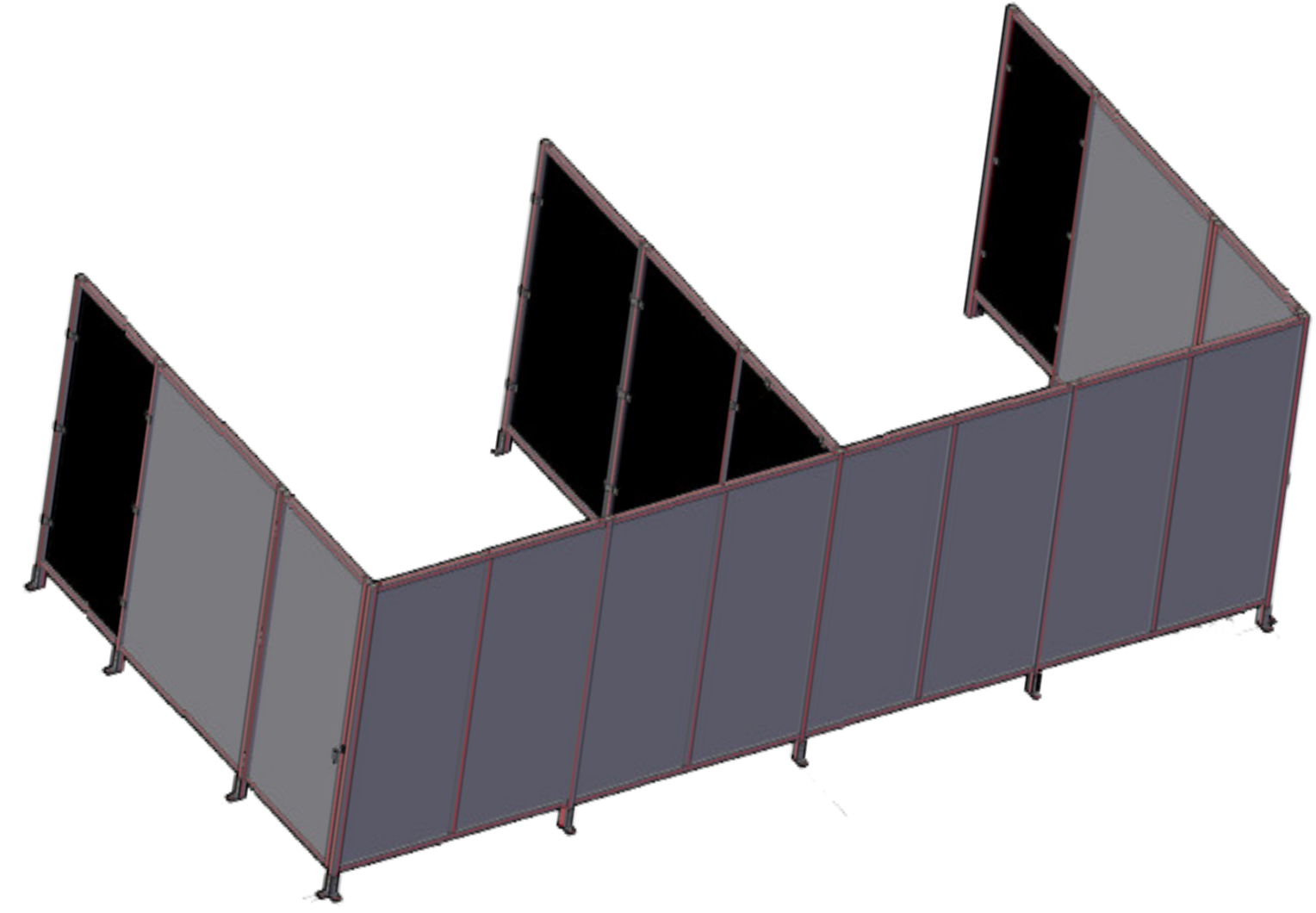

Custom Robot Enclosure

Our team worked to create a custom-designed mechanical guarding that would attach to a wall and be used to enclose two robot work cells. Safety interlock switches are coupled with the doors to ensure a safe stop when the operator enters the hazard area for maintenance and part changeover.